Polypropylene (PP) sheets are becoming increasingly popular across a range of industries due to their durability, flexibility, and cost-effectiveness. These sheets are crafted from polypropylene, a thermoplastic polymer known for its lightweight yet robust properties. In this article, we’ll explore the various applications of PP sheets, the role of PP sheet suppliers and manufacturers, and why businesses should consider partnering with a reliable PP sheet manufacturer.

What are PP Sheets?

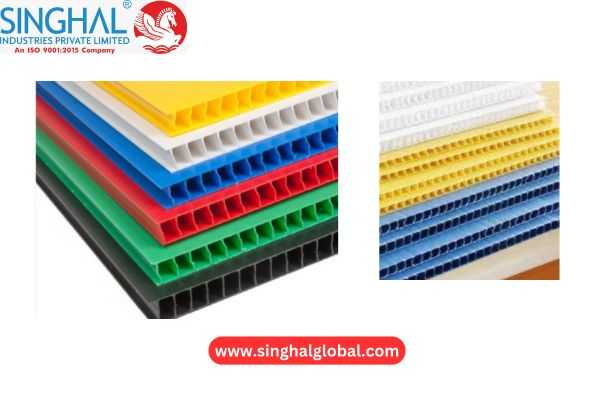

PP sheets are made from polypropylene, a versatile plastic that has gained prominence due to its excellent chemical resistance, high impact strength, and moisture resistance. The material is recyclable and offers superior clarity and ease of fabrication, making it suitable for various uses. PP sheets are available in different thicknesses, colors, and finishes, allowing manufacturers to customize them according to specific industry needs.

Applications of PP Sheets

PP sheets are widely used across different sectors due to their adaptability. Below are some common applications:

Packaging Industry: PP sheets are commonly used in the production of packaging materials such as containers, boxes, and trays. Their lightweight nature and resistance to moisture make them ideal for protecting goods during transportation and storage.

Automotive Industry: In the automotive sector, PP sheets are used for interior trims, panels, and under-the-hood components. Their durability and resistance to high temperatures make them a reliable material in vehicle manufacturing.

Construction Industry: PP sheets are employed in construction for various purposes such as insulation, cladding, and protective layers. Their ability to withstand harsh environmental conditions makes them suitable for outdoor applications.

Stationery and Printing: PP sheets are also utilized in the production of stationery items like folders, binders, and covers, as well as for printing labels and signage due to their flexibility and ease of printing.

Medical Applications: In the healthcare sector, PP sheets are used to manufacture medical trays, disposable syringes, and other equipment that require a high level of hygiene and sterilization.

The Role of PP Sheet Suppliers and Manufacturers

With the growing demand for polypropylene sheets in various industries, the role of PP sheet suppliers and PP sheet manufacturers has become more crucial than ever. They ensure the consistent availability of high-quality PP sheets that meet the requirements of different sectors.

Suppliers: PP sheet suppliers act as intermediaries, providing industries with the required materials. They offer a wide range of PP sheets with varying specifications and ensure that clients receive the right product for their needs. The availability of PP sheets in bulk quantities allows businesses to carry out large-scale operations efficiently.

Manufacturers: PP sheet manufacturers are responsible for producing the actual sheets from raw polypropylene material. A reliable PP sheet manufacturer offers customization options, including sheet size, thickness, color, and texture. They invest in advanced production techniques to ensure consistent quality and supply. Many PP sheet manufacturers also focus on sustainable practices, producing recyclable materials that reduce the environmental impact of plastic waste.

Choosing the right PP sheet manufacturer is essential for businesses to ensure they get a product that meets their specific requirements. A good manufacturer will adhere to strict quality control standards, ensuring that the PP sheets are durable, reliable, and meet regulatory requirements.

Benefits of Partnering with a Trusted PP Sheet Manufacturer

When selecting a PP sheet manufacturer, it’s crucial to opt for one that has a reputation for delivering high-quality products. Here are some benefits of working with a trusted manufacturer:

Customization: A reliable manufacturer can customize PP sheets according to your specific requirements, ensuring that you get the right product for your application.

Consistent Quality: A well-established PP sheet manufacturer will adhere to stringent quality control processes, ensuring that the sheets meet industry standards.

Timely Delivery: With a trusted manufacturer, you can expect timely deliveries, ensuring that your operations are not delayed due to supply chain issues.

Sustainability: Many top manufacturers prioritize eco-friendly production practices, using recyclable materials and minimizing waste.

Conclusion

Polypropylene sheets have proven to be a versatile and cost-effective solution for various industries, from packaging to construction. As demand continues to grow, the role of PP sheet suppliers and PP sheet manufacturers becomes increasingly important in ensuring the availability of high-quality materials.

Businesses looking for a reliable PP sheet manufacturer should consider factors such as customization options, quality control, and sustainability practices to ensure they receive the best possible product. With the right partner, companies can leverage the benefits of PP sheets to improve their operations and reduce costs.

FAQs on PP Sheets

1. What are PP sheets?

PP sheets are polypropylene sheets made from a thermoplastic polymer known for its strength, flexibility, and resistance to chemicals, moisture, and impact.

2. What industries use PP sheets?

PP sheets are used in various industries, including packaging, automotive, construction, printing, and healthcare for different applications such as packaging, insulation, and medical equipment.

3. What are the benefits of PP sheets?

PP sheets are lightweight, durable, moisture-resistant, cost-effective, and recyclable, making them ideal for a wide range of applications.

4. How do I choose a reliable PP sheet supplier or manufacturer?

Look for manufacturers with a good reputation, strict quality control standards, customization options, and a focus on timely delivery and sustainability.